正確に管理するため”人を介さない完全自動化”へ

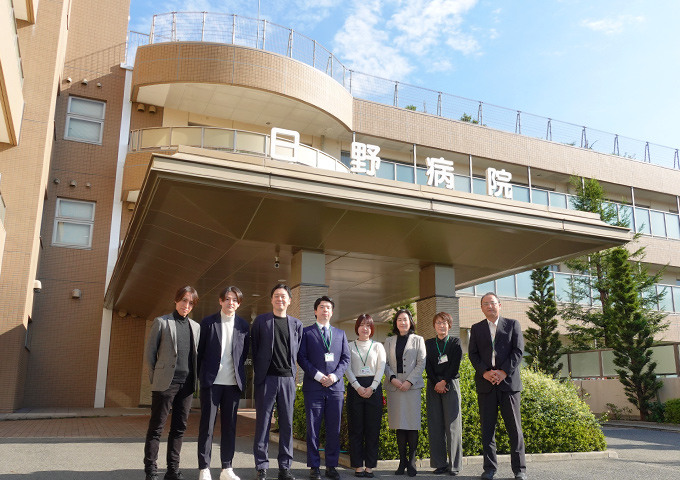

日本ステリ株式会社

- ・1日最大6回、洗剤消費量を目視で確認する作業が負担になっていた

.png)

- ・人による確認作業がなくなり、計測データが残るためリスク回避に役立っている

今回は、スマートマットクラウド導入に至るまでの経緯やきっかけ、導入後のご感想などを、品質管理部 品質向上課の黒部様にお伺いしました。

貴社の事業内容について教えてください

病院で患者様に使用した器材を洗浄・滅菌するサービスを行なっております。 病院の中には、医療器材の洗浄・組立・滅菌等を行う「中央材料室」という部署があり、我々はその部署内での業務を受託しています。

患者様に使用され返却された器材を、洗浄機と滅菌機を使って”感染性の除去→器材の洗浄→器材の滅菌”といった業務を行なっています。

スマートマットクラウドを導入する前の在庫管理や発注の課題はどのようなものだったのでしょうか?

洗浄作業の効率化と作業者の負担軽減

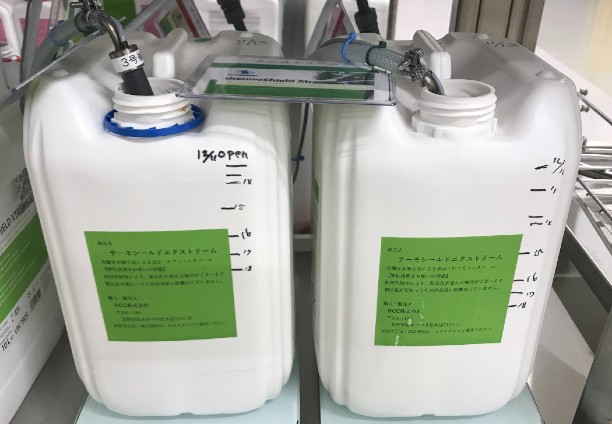

医療器材を洗浄する洗浄機は洗浄剤が自動投入されるようになっており、基本的には正しく計量・投入されるのですが、故障が発生すると洗浄剤が吸い上げられなくなり、十分な洗浄効果が得られないことになるため、このリスクを回避する運用を構築する必要がありました。

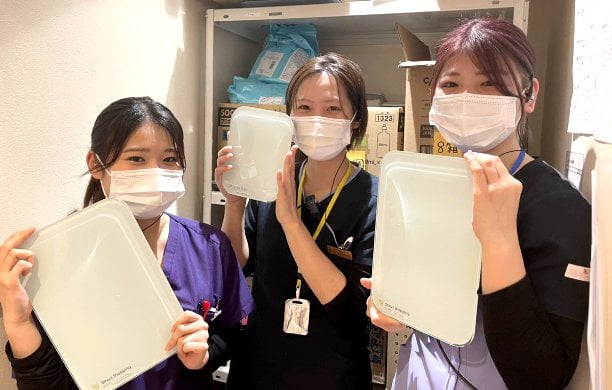

そのリスク回避策として、洗浄剤ボトルに線を引き、確実に洗浄剤が消費されているか目視で確認・記録を行っていました。

洗剤消費量を目視で確認する運用方法も課題に

1日数回、液面の位置を人の目で計測し、その都度、液面の位置を洗剤ボトル上に線を引いて印をつけていました。

洗浄剤が消費され、液面の位置が下がっているかを確認することで、確実に洗浄剤が自動投入されているか確認していたのです。

また、洗浄剤は床面や低い場所に設置されているため、作業者が毎回確認する際の負担も課題となっていました。

液面の位置を線を引いて目視で確認

液面の位置を線を引いて目視で確認

スマートマットクラウドをどのように運用されているのですか?

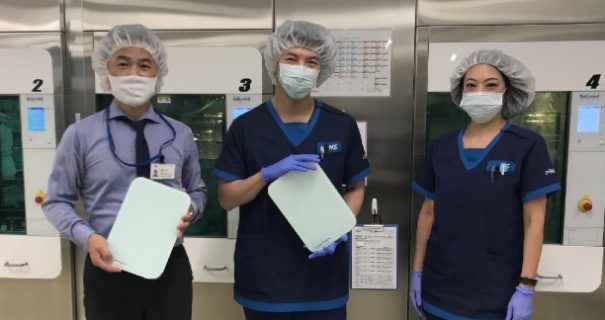

器材を洗浄する洗浄機に取り付けられている液体洗浄剤が、自動投入された際にきちんと消費されているのか、スマートマットクラウドで自動計測しています。

その洗浄機の下に設置してある、満タン時4kgほどの液体洗浄剤のボトルの下に敷いて使用しています。

設置風景

設置風景

スマートマットクラウドをお知りになったキッカケはどういったものだったのでしょうか?

自社の業務自動化の観点で情報収集している際にインターネットで見つけました。その後、展示会でコンタクトを取って商談させていただきました。

他の在庫管理システムも比較・検討はされていましたか?

当初、洗浄剤投入課題について(協力企業と)自社開発を検討しておりました。ただし、洗浄装置1台当たりの導入コストは30~50万。

スタンドアローン(※ネットワークや他の機器に接続しないで、単独で動作している環境)で重量情報を記録紙によって目視確認するというものでした。

また設置の際に電源が必要になる課題もあったため、電源がいらず容易に設置できるものがないか検討していました。

スマートマットクラウドの導入に至った決め手を教えてください

検討していた自社開発のシステムでは、各施設への導入コストも高く、情報という観点でもデジタルデータ化、データ集約されたものではありませんでした。

一方、スマートマットクラウドはハード、ソフトウェア双方使用できることにより簡単にデジタル化できること、また低価格といったところが決め手でした。

スマートマットクラウドを導入して実感された効果はどのようなものでしたか?

1日最大で6回程度行われる、人による確認作業がなくなりました。 導入目的であった洗浄剤の消費が正確に計測されるのも、非常に効果として実感しています。

それだけでなく計測したデータも残りますし、CSVとして出力することができるのも、とても便利ですね。また、洗浄機が不具合を起こした場合のリスク回避にも効果が得られていると実感しています。

スマートマットクラウド管理画面

スマートマットクラウド管理画面

現場のスタッフの反応はどのようなものでしたか?

洗浄剤の入ったボトルは、狭い場所や洗浄機の下に設置されていることが多いので、人の手で確認していた際には、狭かったり、暗かったり、汚かったりと本当に大変な作業でした。

そういった作業自体がなくなったので、「コア業務に注力できるようになった、顧客対応に時間がとれるようになった」と喜びの声をいくつも聞いています。

インタビューのご協力ありがとうございました! 機器を組み合わせ、業務の完全自動化に成功された日本ステリ様。今後も多くの企業様の課題解決のお役に立てるよう精進していきます

日本ステリ株式会社|スマートマットクラウド導入の概要

- 導入目的

- 在庫データの取得

- 設置場所

- 病院内・中央材料室

- 管理商材

- 満タン時4kgほどの液体洗浄剤

- スマートマット導入の決め手

- 低価格、入出庫データの自動取得